Why stagnation flushes are so important: the basics of drinking water hygiene

Regular stagnation flushes are essential at times when the specified normal operation of a building’s installation cannot be assured. This is because an interruption to specified normal operation risks degrading drinking water quality. To avoid long periods of stagnation in the piping – which are not permitted by law, since this can lead to the excessive proliferation of Legionella and other bacteria – a number of rules need to be observed. Which is easy to do – with solutions from SCHELL.

Following good technical practice to ensure specified normal operation

First and foremost, the generally accepted codes of practice need to be followed. To maintain drinking water quality in buildings in Germany, for example, relevant regulations are the DIN EN 806 and DIN 1988 series, DVGW W551 and VDI 6023. These set out the recognised industry best practice that needs to be followed to maintain drinking water hygiene at an acceptable level. This ‘specified normal operation’ requires an exchange of water at each tapping point in the drinking water installation at a maximum interval of 72 hours. If this can’t be assured by normal usage, this is considered an interruption in use that requires action to be taken (see table). Accordingly, the facility manager must ensure a complete water exchange every three days (72 hours). If this cannot be assured by regular use of the installation, then an exchange of water can be simulated with (automatic) stagnation flushes. While these flushes can restore specified normal operation, other aspects need to be considered: to be effective, stagnation flushes not only need to cover all of the fittings in the building but must also conform to other rules.

Taking note of temperatures and creating turbulent flows

Drinking water hygiene is also critically dependent on water temperature. If cold water becomes too ‘hot’ or hot water too ‘cold’, then bacteria in the water can spread uncontrollably. In a properly planned and executed drinking water installation, the temperature in the cold water lines must not exceed 25 °C. The hot water supply, on the other hand, should be kept at a minimum of 55 °C. For good drinking water hygiene, maintaining these temperatures is essential. If temperatures fall below or rise above these values for longer periods, stagnation flushes can trigger an exchange of water that flushes the ‘wrong’ hot or cold water out of the piping.

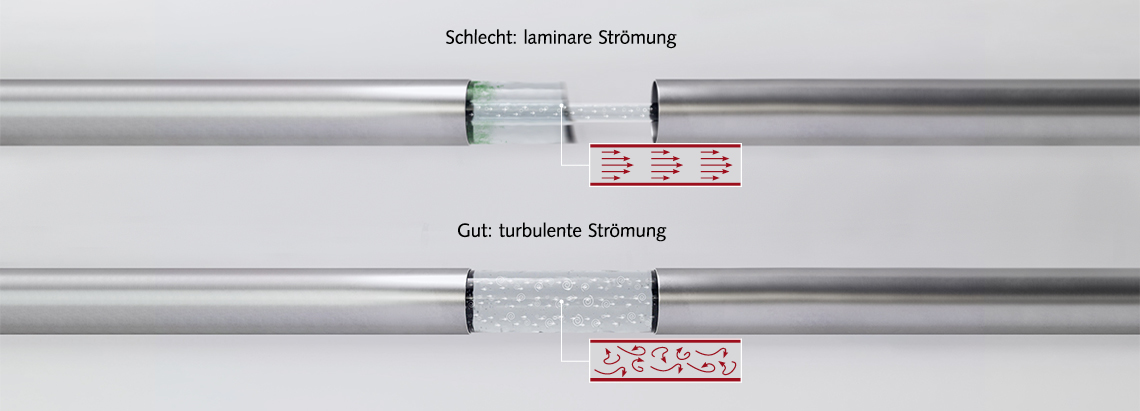

Avoiding the ‘pipe-in-pipe’ phenomenon is also important. If buildings are used by many people at peak times, then the installation piping must be designed for this level of heavy use. If only a few fittings are used at other times, however, then water near the pipe walls can stagnate, even if water is being tapped (‘pipe-in-pipe’ phenomenon). Most of the water flows through the centre of the piping, while the remaining water hardly moves. To achieve a proper exchange of water in this situation, a turbulent flow now needs to be created. Particularly in the case of large pipe diameters, this is only possible by flushing multiple fittings at the same time.

Many challenges – and one solution: SCHELL SWS

The range of electronic fittings from SCHELL offers an excellent starting-point. These fittings can be easily programmed with stagnation flushes for any installation. SCHELL’s varied range of high-quality, elegant fittings offers a way to save resources for the most discerning customer. For an even more straightforward and comprehensive approach, fittings can be configured and controlled with the SCHELL SWS Water Management System. SWS offers the centralised programming of stagnation flushes across groups of fittings, for example, which makes it possible to create the kinds of concurrencies some installations need to avoid the pipe-in-pipe phenomenon. Temperature sensors can also be integrated with SCHELL SWS, so as to offer a way of checking compliance with water temperatures. When the system is expanded to include the SMART.SWS online service, stagnation flushes and many other parameters can be viewed and even adjusted online. SWS not only helps you to maintain proper levels of hygiene in your drinking water installation but also ensures it can be operated efficiently and economically.

More in-depth coverage of the topic of drinking water hygiene is also provided by the SCHELL SWS Manual.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)