Water management - Drinking water hygiene

SWS – making life easier for facility managers

Facility management involves a lot of tasks that are often time-consuming and complicated.

Read more

16-minute read

Drinking water installations on semi-public, public and commercial premises present planners, tradespersons and facility managers with an extensive set of challenges. The German Drinking Water Act requires compliance with generally recognised codes of practice as the basis for legally compliant operation. Drinking water quality must be maintained at each tapping point. Building operators are responsible for ensuring that a sufficient exchange of water takes place –

at least every 72 hours. This is because, in the event of interruptions to operations, the water stagnates in the pipes for too long. This allows potentially harmful microorganisms to propagate to unacceptable levels. Preventing this requires the regular and correct exchange of water.

As experts for intelligent solutions that provide support for maintaining drinking water quality, we can help you maintain the drinking water quality in your building while increasing building efficiency. The SCHELL SWS Water Management System allows many electronic SCHELL fittings and corresponding SCHELL products to be networked and controlled centrally – providing an ideal basis for the hygienic and efficient operation of the drinking water installation.

In this article, we introduce you to the award-winning SCHELL SWS Water Management System: this is designed along modular principles and is easy to both modify and expand. Discover how easy planning and installation can be, and how the system supports both efficient and hygienic operation.

SWS ensures all SCHELL fittings in a building can be networked, controlled and managed. If needed, settings can even be adjusted for each fitting individually. Flexible networking using wireless and/or wired connections offers advantages for retrofitting – even to existing properties. If power sockets are in short supply, wireless networking is an option, with power being supplied by batteries.

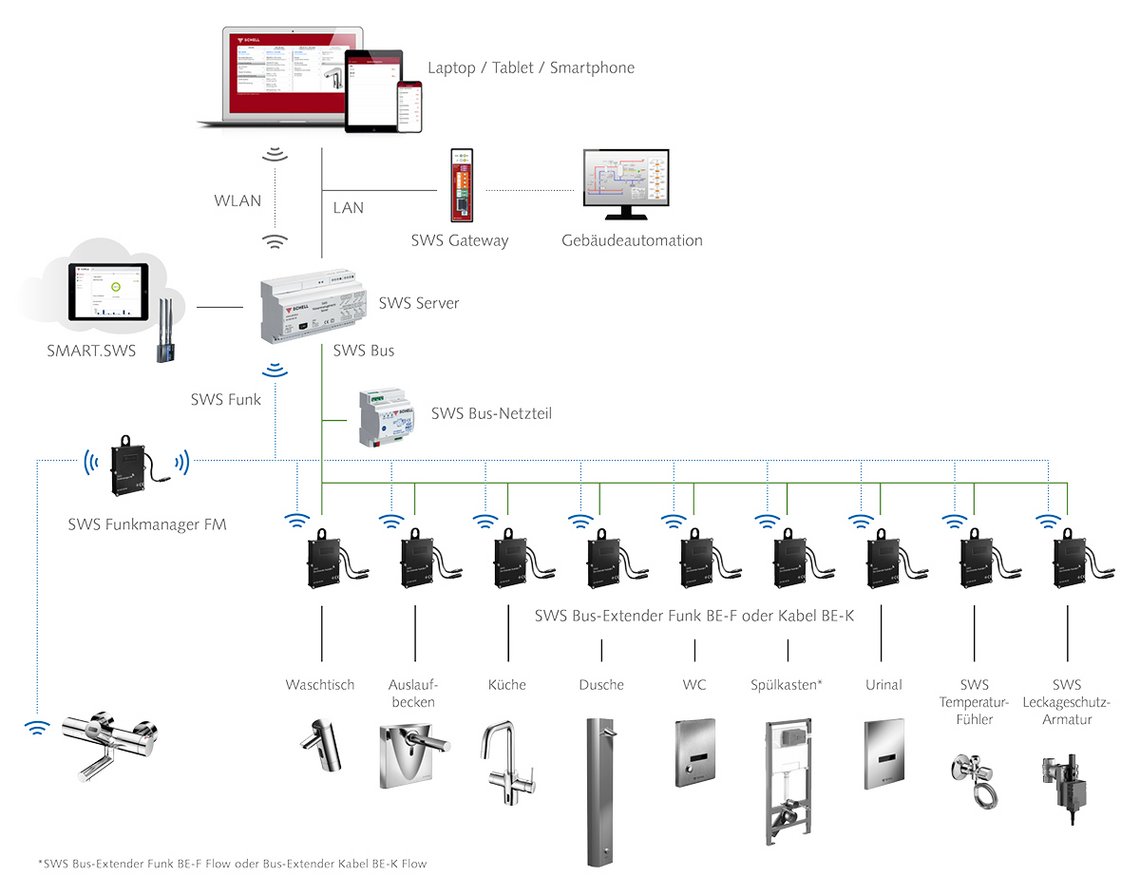

SWS works to the principle of ‘many features from a few components’. The centrepiece is formed by the SWS Water Management Server, which networks together all of the fittings. Programming, control and monitoring of the fittings is handled centrally.

SWS helps to maintain drinking water quality with automated stagnation flushes. These flushes can be programmed centrally, and then executed and logged at specified times. With the option of assigning fittings to groups, stagnation flushes can be triggered across multiple fittings at the same, preconfigured point in time. This enables easy simulation of ‘specified normal operation’. Maintenance work, such as replacing the batteries in the fittings, can be planned preventively and effectively.

For facility managers, a deployment of the SCHELL SWS Water Management System offers key advantages. SWS helps building operators to operate their drinking water installation hygienically while logging all activities taken to maintain drinking water quality as required by law – even during fluctuations in facility capacity usage. These automated processes save time and cut costs, and offer building operators valuable support for keeping their drinking water installations legally compliant.

SWS can either be used as a standalone solution or integrated into the central building control system by means of gateways.

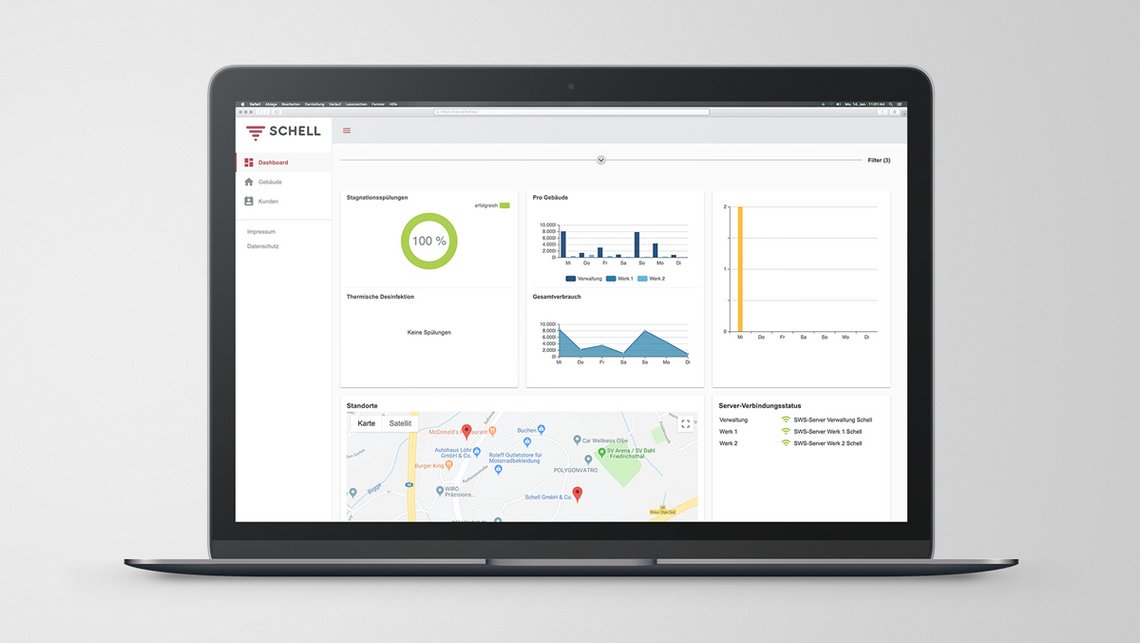

The SMART.SWS add-on is a browser-based online service that offers remote access to SWS installations from anywhere in the world.

The SCHELL SWS Water Management System consists of individual components that can also be retrofitted to an installation afterwards.

At the heart of the system is the intelligent server and its software. The server is responsible for the centralised programming of fitting parameters, stagnation flushes and thermal disinfections, as well as analyses and logging. Data from up to 64 subscriber units is transferred wired and/or wirelessly. Multiple SWS servers can be operated in parallel. With SWS gateways, the SWS server can also be integrated into a central building control system.

The wireless manager is used to bridge longer wireless distances: it functions as a repeater and is powered by a mains adapter.

The BE-K wired bus extender transfers data between the fitting and the SWS server along a cable up to 350 m in length (total length of all cables must not exceed 1000 m). The same cable provides a power supply to the BE-K and fitting.

The BE-F wireless bus extender enables wireless data transfer between the SWS server and the electronic fitting. The power supply can be provided either via the fitting’s battery compartment or via a mains adapter. When supplied with mains voltage, the wireless bus extender also functions as a repeater (wireless mesh network).

The bus mains adapter provides power to all of the wired bus extenders and their networked fittings as well as the SWS server.

The gateways enable the SWS Water Management System to be integrated with a central building control system. A gateway translates the SWS protocol into the standard bus protocol required. SWS gateways for all popular protocols are available, depending on the protocol and data points that you require. One SWS gateway is required for each integrated SWS server.

With SMART.SWS, the innovative add-on to SWS, users get online access to analysis data plus key status messages and reports for any building – and wherever in the world they happen to be.

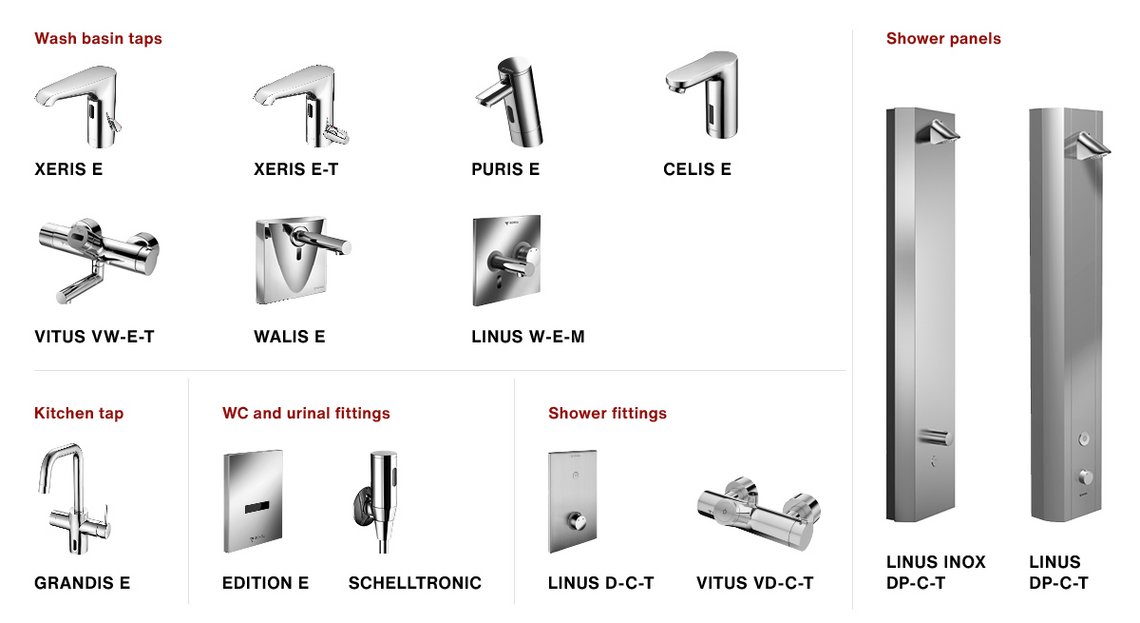

With its set of perfectly coordinated components, SWS networks and controls a wide range of electronic SCHELL fittings at all relevant tapping points for wash basins, in kitchens and showers, and on WCs and urinals.

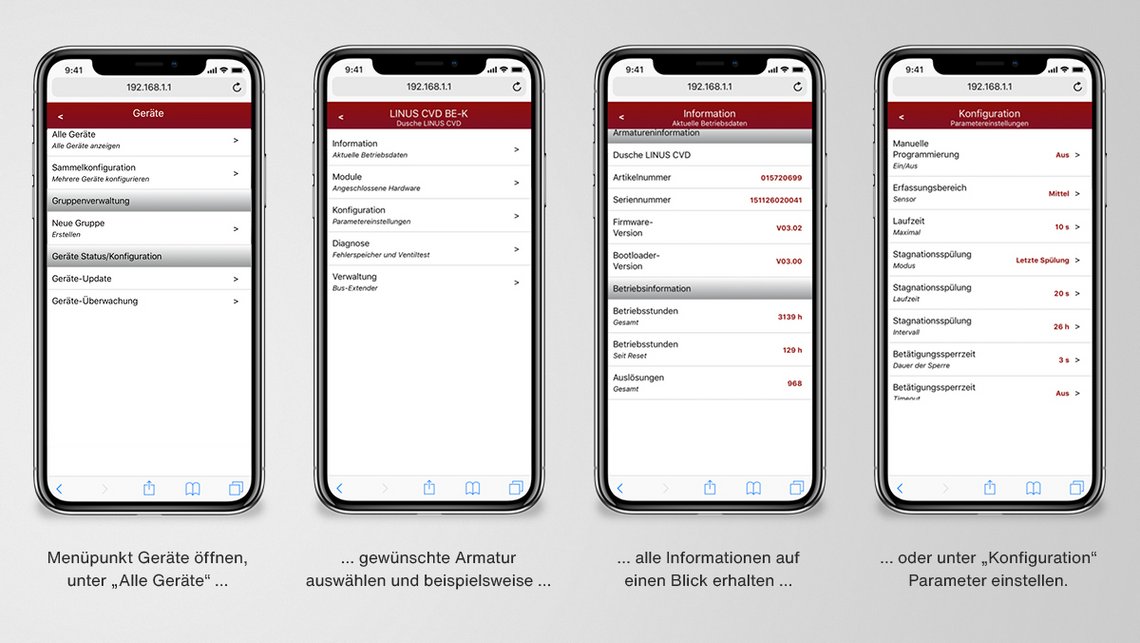

The structure of the SWS network is designed to match the respective property. Centralised access to all networked fittings makes the parametrisation and commissioning of the installation especially convenient. The wide range of configuration options for the software ensures a maximum level of flexibility:

up to 64 subscribers can be integrated with a Water Management Server over a wired or wireless connection. Wired and wireless networks can be set up individually or organised in parallel as part of a mixed-mode network.

SWS can be integrated into a central building control system via an SWS gateway.

Wired networks can be individually adapted to the property independently of network typologies. Since the network cable is used for both data transmission and power supply, only one cable needs to be installed. The system enables flexible networking for star, series and tree structures. Hybrid models are also possible.

An SWS wireless network enables networking without intervention in the building substance. Wireless range is achieved by setting up a mesh network and by the optional integration of wireless managers.

Centralised access to all networked fittings makes setting fitting parameters and commissioning the installation especially efficient. One particular advantage here is that the software can be used to group fittings with the same properties together and configure them in a single operation. In the event of a change of use, the fitting parameters can simply be modified to suit the new conditions.

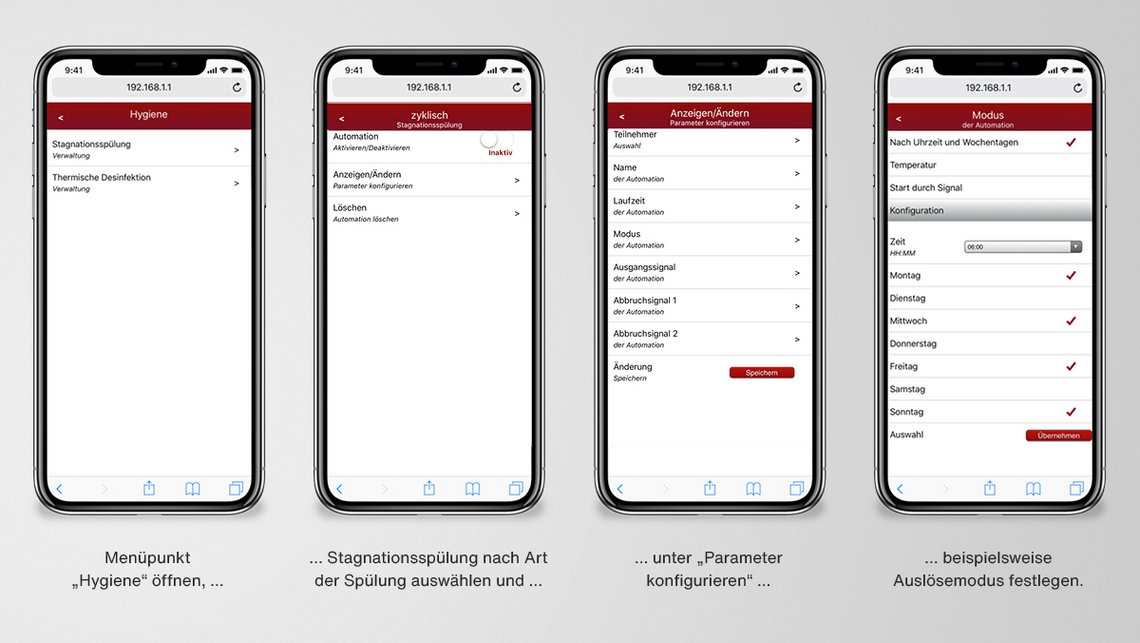

For simulating the installation’s specified normal operation, the required stagnation flushes are created and managed in the SCHELL SWS Water Management System. Here, these flushes can be modified to suit local conditions and user behaviour. You define the length of the flow time for the flush and whether it is cyclical, weekly, temperature-controlled or controlled manually by an external signal.

The following scenarios can be programmed:

a) The selected fittings flush cyclically every x hours for y seconds. The time is calculated as starting from the activation of the function.

b) When flushing according to the weekly schedule, the user programs the weekday, time and duration of the flush.

c) Stagnation flushes are performed when a target temperature at a selected sensor is exceeded or not reached. Example: The cold water temperature (PWC) exceeds 25 °C, the hot water temperature (PWH) falls below 55 °C.

d) Combinations of different stagnation flushes are also possible.

Data security is a topic taken seriously with SWS: The server, Wi-Fi connection and wireless channel are secure.

The system is password-protected. Access rights can be defined in User Management.

The wireless bus extenders work with the server to set up a wireless network that is optimised for building automation.

Like other software-based applications, SWS is continuously adapted to technical developments. We therefore provide updates for all essential system components that you can obtain free of charge.

SWS makes your day-to-day work easier. User management is used to grant various individuals specific access rights. For example, cleaning staff can independently switch on the cleaning stop for a specific area. Each user has their own password, which they can change on their own. The relevant functions for the respective user are activated using profile management tools. This means that people at different levels in the hierarchy can benefit from the advantages offered by SWS without affecting other areas.

By using SWS gateways as an interface, SWS can be integrated into all leading central building control (CBC) systems. The communication setup here involves the central building control system querying the current status of a data point (e.g. temperature). The SWS gateways ‘translate’ this query and receive the necessary data from the water management server, which they translate back and forward. The CBC system can use SWS gateways to access selected information from SWS.

Each SWS gateway is available for 200, 500, 1,000 and 2,500 data points. The building operator decides which data points should be monitored by the central building control system.

SWS helps to avoid complex building work involving chiselling into masonry to replace piping: outsized pipework cross-sections and a lack of concurrency in usage present risks to drinking water quality in situations where operation at full load, as originally planned, is now not achieved with regular use. The solution with the SWS Water Management System is to use SWS to combine networked SCHELL fittings into groups for executing regular stagnation flushes. By forming these groups, the fittings present in a group can be activated at exactly the same time for stagnation flushes, which they then carry out together. The generates the necessary concurrencies, which are important to ensure that high velocities are achieved by the water in the piping, which result in the turbulent flows. Compared with construction work involving masonry, installing SCHELL products is a more sustainable approach, as fewer resources are required.

In the event of a change of use for the property, the programming of the fittings can be easily modified.

Renovations to existing properties are often subject to annually reviewed budget limits. For municipal projects, for example, those responsible can often only commission renovations in phases. SWS is ideal for meeting such needs. In the case of a school campus needing to modernise several of its buildings, renovations can be spread across several years: with the modular approach taken by SWS, it can be expanded step by step – and without requiring system downtime.

If a school needs to renovate several buildings, this project can be tackled in several phases. Within an individual building, it is also possible to equip tapping points with network-ready fittings one after the other.

An innovative add-on to SWS is the browser-based online SMART.SWS service, which gives facility management remote access (using an encrypted data channel) to all of their facilities at a glance. For building operators, not having to visit the individual buildings to manage fittings and installations is often beneficial – saving them valuable time, trips and expenditure on personnel.

SMART.SWS offers an overview of the most important runtime parameters for the installations managed with SWS. Depending on their assigned roles, authorised users can also work with SWS servers individually or as a group. SMART.SWS users merely require an internet connection and an installation that uses SWS. From a single server-level view to a general overview of all of the buildings: messages, calculated water consumption and much more is all attractively visualised by SMART.SWS. The visible elements vary according to the user role, ensuring that users only see the data that is relevant to their task area: Building owners have access to data for all of their buildings, facility managers will see just a single building, while technicians may be given access only for a single server, for example. If changes occur in use, such as during holidays, stagnation flushes and other parameters can be adjusted via an encrypted remote channel, and therefore optimally set up to maintain drinking water quality and ensure economical operation of the drinking water installation.

SWS recently received an international accolade in recognition of its unique functionality: SCHELL’s SWS Water Management System and its innovative SMART.SWS add-on have received the World Future Award 2023. As an award-winning “best water management system”, SWS now joins the ranks of products that the expert jury believes will work to change global business and set the pace for the future.

SWS:

SMART.SWS:

The SCHELL SWS Water Management System is designed around a modular approach, with just a few, perfectly matched components providing optimum flexibility for both existing properties and new developments. SWS can be used for the central networking, control and monitoring of many electronic SCHELL fittings. And with SMART.SWS, this can even be achieved worldwide via remote access. By utilising SWS, operators of drinking water installations achieve valuable support for ensuring the legally compliant operation of their drinking water system. SWS can help these operators to balance the needs of maintaining drinking water quality while saving water. SWS also helps building operators to save valuable time and expenditure on personnel. Thanks to SWS, the exchange of water required by law can take place even under difficult conditions, such as seasonal interruptions in use, as an automated process that is logged with a legally compliant audit trail.

Water management - Drinking water hygiene

Facility management involves a lot of tasks that are often time-consuming and complicated.

Read moreElectronic fittings - Drinking water hygiene

Fittings with a stagnation flush option are important if support is required for maintaining water quality in a building. SCHELL offers a diverse portfolio of these types of products, which are...

Read moreElectronic fittings - Building solutions - Leak protection - Sustainability - Planning aids - Renovations - Drinking water hygiene

Alongside optimisation options for water and energy efficiency, a key advantage of digitalisation buildings lies in the greater cost-effectiveness of building operations. This applies in...

Read more