SWS – making life easier for facility managers

4-minute read

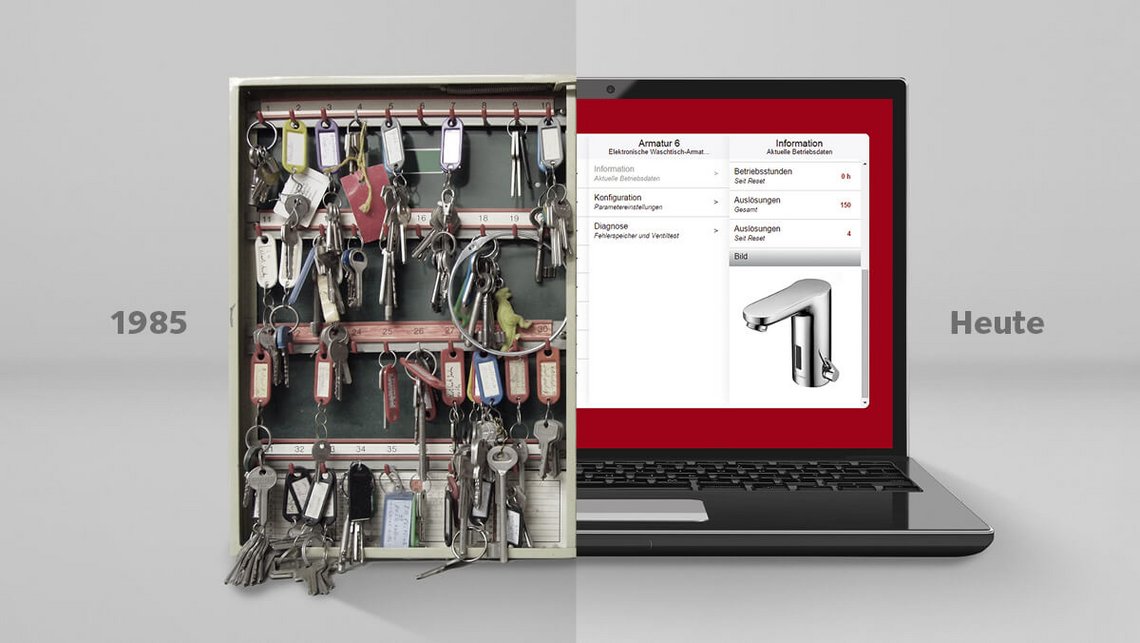

Facility management involves a lot of tasks that are often time-consuming and complicated. After all, you typically need to be on site when it comes to maintenance work, repairs or even just planning, managing, monitoring and organising day-to-day operations. This takes time – and costs money. SCHELL provides digital technologies to support the work of facility managers, ensuring greater efficiency, time savings and convenience in their day-to-day activities.

SWS as an innovative tool

One important task handled by facility managers is maintaining drinking water quality. After all, protecting user health is a top priority. At the same time, buildings should also be operated efficiently and sustainably. For such tasks, SCHELL’s Water Management System SWS is an innovative tool that helps to ensure the hygienic and efficient operation of the drinking water installation. SWS makes it possible to network many types of electronic SCHELL fittings together. Programming, control and monitoring is handled centrally by the SWS software. If necessary, gateways (which are available for all popular bus protocols) can also be used to integrate SWS into a central building control system.

Centralised control, logging and monitoring

Facility management is responsible for ensuring compliance with drinking water legislation and therefore ensuring a complete change of water in the drinking water installation after no more than 72 hours. Thanks to SWS, this water exchange can be handled automatically by centralised stagnation flushes. These can be programmed precisely to match local requirements and are then triggered automatically. SWS can also be used to group fittings together so that they can be flushed simultaneously. These groups work to create high flow velocities that produce the turbulent flows which are typically essential in order to simulate specified normal operation. As a result, facility managers do not need to waste time operating fittings manually or making time-consuming tours of the entire building. At the same time, automated flushes are more precise and economical than manual flushes, since exactly enough water – no more, no less – flows through the system. SWS also permits operational parameter monitoring. This lets you identify whether fittings have been used, for example, as well as error states, batteries that are nearly empty and the automatic triggering of your configured stagnation flushes. All of this is also logged in the system, which ensures maintenance work is completed in a targeted and efficient manner. SCHELL’s Water Management System SWS therefore helps facility managers keep tabs on their drinking water installation round the clock.

Mobile and convenient with SCHELL SMART.SWS

SCHELL SMART.SWS extends SWS to include an online service that makes water management even simpler and more digital. Thanks to this innovative add-on to the Water Management System SWS, facility managers can get updates on stagnation flushes or water consumption data for any of their fittings in any of their buildings while out and about. This means that they are no longer forced to be on site, and can check and adjust stagnation flushes or operating parameters for fittings – such as follow-up times – even remotely if need be. This makes work much easier, especially if facility management staff have to take care of multiple properties. With SMART.SWS, they can keep tabs on all of their buildings at the same time. To ensure only relevant buildings are shown to facility management personnel, access rights can be assigned individually beforehand. Water management has never been so convenient as it now is with SMART.SWS.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)