The Panorama Sauna in Grafschaft-Holzweiler is one of the most popular sauna venues in the Cologne/Bonn metropolitan area. In the course of a comprehensive extension project, SCHELL products were chosen that could enhance the unique spa experience at this site while also maintaining drinking water hygiene.

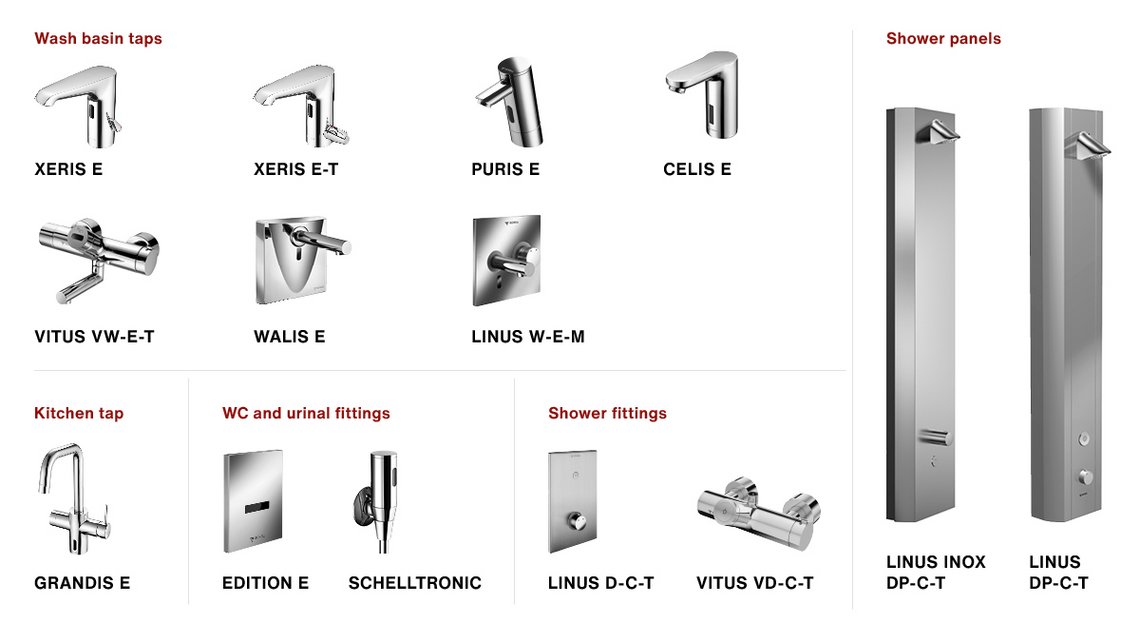

Challenge: A new extension to the sauna area was intended to complement the sauna with its high-end design. Alongside a modern and appealing design, the sauna owners were looking for premium, robust quality capable of handling high visitor numbers. Requirements for energy efficiency, drinking water hygiene and user hygiene also needed to be met.

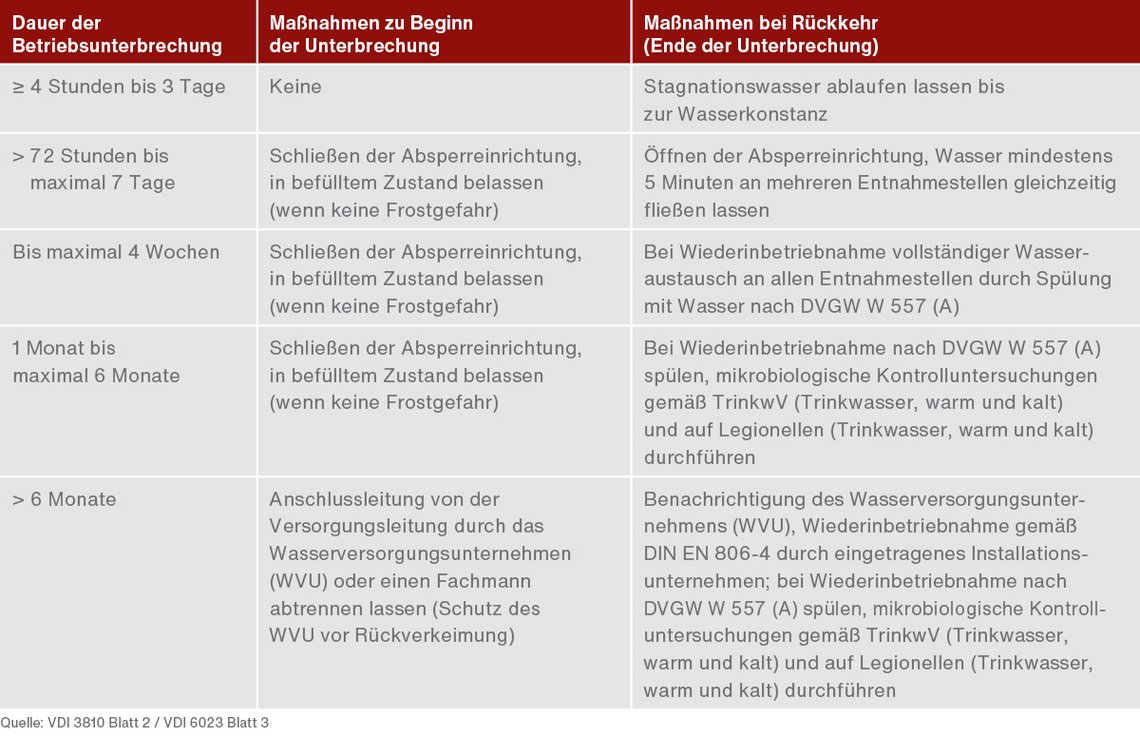

Solution: SCHELL offered an impressive package of high-end, modern design, first-class advice and assistance, and exceptional product quality. Robust LINUS Inox DP-C-T exposed shower panels with ThermoProtect thermostats offer impressive reductions to water consumption. SWS can be used to carry out automated stagnation flushes, which can prevent the excessive propagation of bacteria harmful to health, such as Legionella. As a result, the shower panels and SWS help to ensure the hygienic and trouble-free operation of the showers at Panorama Sauna into the long term.

Read our case study to find out more about the Panorama Sauna extension project.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)