Cutting up-front investment and running costs with water-saving fittings – and for LEED, BREEAM and DGNB certification

15-minute read

Approaches to saving energy and water are not just key concepts for now and the future. When it comes to buildings, this is why the energy transition really needs the help of the HVAC and sanitation industry. Lower rates of water flow at all tapping points – as typically required by ecological building certification systems like LEED, BREEAM or DGNB – help to reduce water consumption and, in the case of hot water, overall energy usage as well. The effects that measures like this can have on the initial investment costs for drinking water installations have been investigated by Luca Güsgen, owner of Güsgen Heizung Klima Sanitär in Soest, North Rhine-Westphalia, in his bachelor’s thesis. Practical expertise was offered here by SCHELL’s drinking water hygiene specialist, Dr Peter Arens.

Bachelor’s thesis from industry expert reveals key savings for initial investment costs

DWD climate data analysis as theoretical basis

LEED, BREEAM and DGNB – caution is advised for existing properties

Planning needs to account for reduced calculated flows (DIN 1988-300)

Practical example: recalculation for a residential building with six apartments

Planning with reduced values cuts initial investment and running costs

Bachelor’s thesis from industry expert reveals key savings for initial investment costs

The bachelor's thesis offers a number of interesting insights of relevance for the HVAC and sanitation industry. For Luca Güsgen discovered – as Dr Peter Arens explains – “the economic potential of perhaps the only ecological measure that directly reduces the cost of initial investment and running expenses without endangering drinking water hygiene.” This technical article, published in the IKZ and BundesBauBlatt journals, reveals savings of up to 40 percent by weight for pipes and connectors, and 40 percent for water and waste water charges. These calculations were based on a six-unit residential building.

DWD climate data analysis as theoretical basis

The topic for the bachelor’s thesis, for submission to the South Westphalia University of Applied Sciences, was provided by Arens: Namely: ‘Drinking water installations: impact of reduced drinking water consumption in the context of tighter drinking water hygiene regulations’. In the theoretical part of the thesis, Güsgen focused on analysing climate data from the German Meteorological Office (DWD).

Increase in hot days and greater demand for water

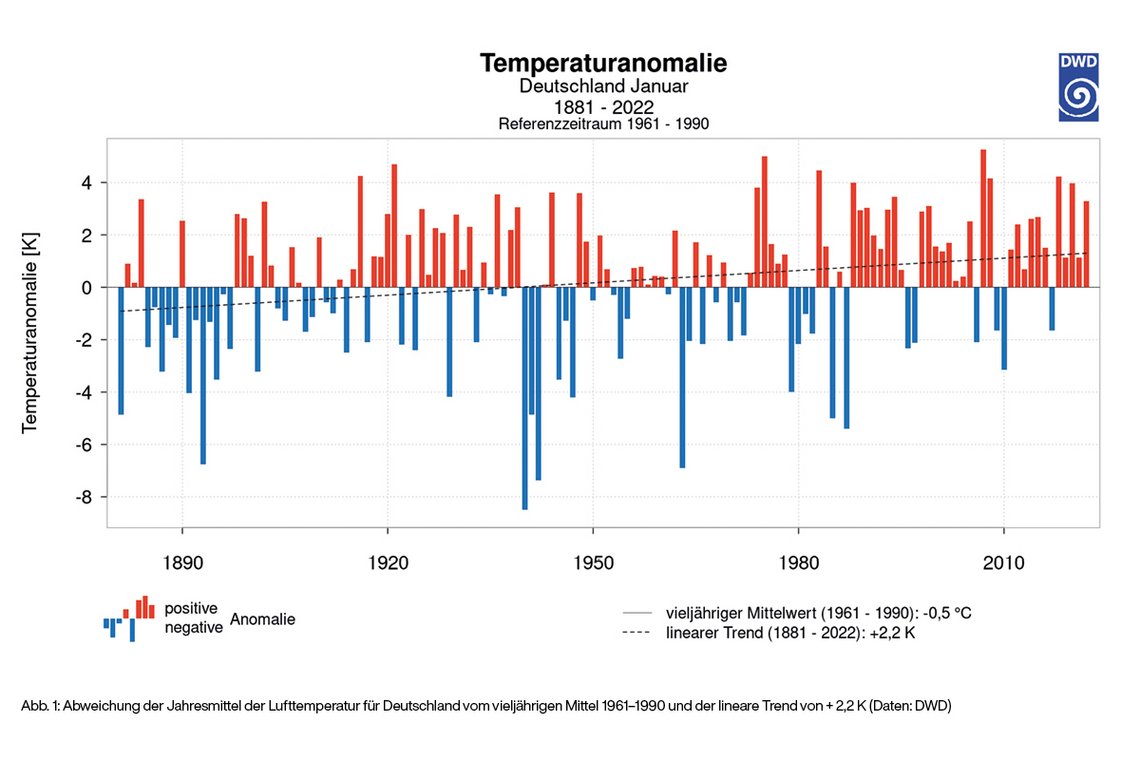

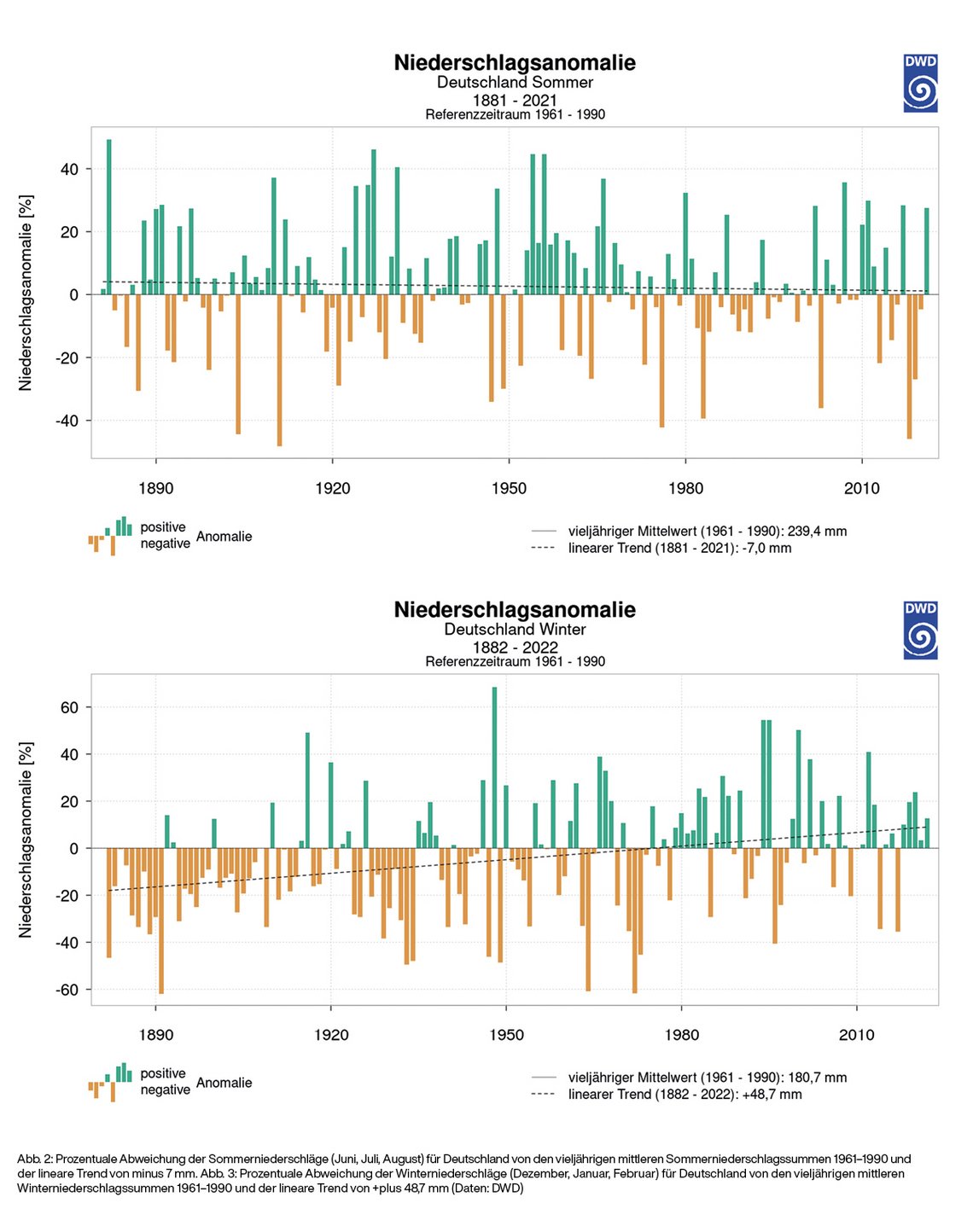

Among other things, climate data from the DWD show a significant uptick of +2.2 K in the linear trend for temperatures in the period 1881 to 2022 (fig. 1). In contrast, however, the trend for rainfall has yet to follow a negative trajectory: on the basis of the respective annual mean of precipitation anomalies in the period 1881 to 2022, rainfall in summer has declined in Germany in recent years, but this has been balanced out by a significant increase in winter (fig. 2 and 3).

While this does seem reassuring, the bachelor’s thesis goes on to note that current climate model calculations show precipitation decreasing in summer by as much as 40 percent, even as rainfall increases in autumn and winter. Overall, climate data authors Krahe and Nilson (2020) assume that precipitation will increase by some 2.5 percent, while available volumes of water will decrease by around 10 percent, since rates of evaporation from land and surface waters will increase due to higher temperatures. In this context, one should also remember that demand for water will also rise significantly in the agricultural sector.

Options for saving water without compromising on drinking water hygiene

In light of these facts, Güsgen aimed to use his thesis to determine the options that are already available for minimising water consumption in domestic households. A key criterion here was avoiding the need to compromise on user comfort or drinking water hygiene – because inconveniences experienced during hand washing and showering or impairments to drinking water quality would endanger the acceptance and utility of these potential options.

LEED, BREEAM and DGNB certification – caution is advised for existing properties

While the three leading systems for ecological building certification – LEED, BREEAM and DGNB – do require lower levels of water consumption, both in new and existing properties, they do not consider any issues relating to maintaining water quality. Overall, water consumption savings make up between 2.3 and 10 percent of the total score, depending on the certification system. These are not standalone measures, however, as Arens cautions: “What should certainly be avoided is reducing the litre-per-minute flow at tapping points so that it actually drops below the calculated flow that was used to determine the dimensions of the piping system. If water consumption for an existing building is simply reduced by 50 percent, for example, this has consequences for drinking water quality. For an existing drinking water installation, this lack of adequate usage of the system would cause the water to stagnate in the piping. This could result in an increase in material shedding into the water, plus the excessive spread of bacteria.”

Arens also questions the wisdom of looking at flows in isolation: “We really need to consider whether a wash basin tap with a flow rated at 1.32 l/min (as with LEED) actually does save more water than a tap rated at 3 l/min – because people always need a certain amount of water to properly rinse soap off their hands, for example. In this example, handwashing with a tap rated at 1.32 l/min simply takes longer: no water savings are achieved at all, but the user does suffer in terms of convenience.” Accordingly, the savings required by such certification may not ultimately be satisfactory and may actually work to endanger drinking water hygiene in existing properties.

Planning needs to account for reduced calculated flows (DIN 1988-300)

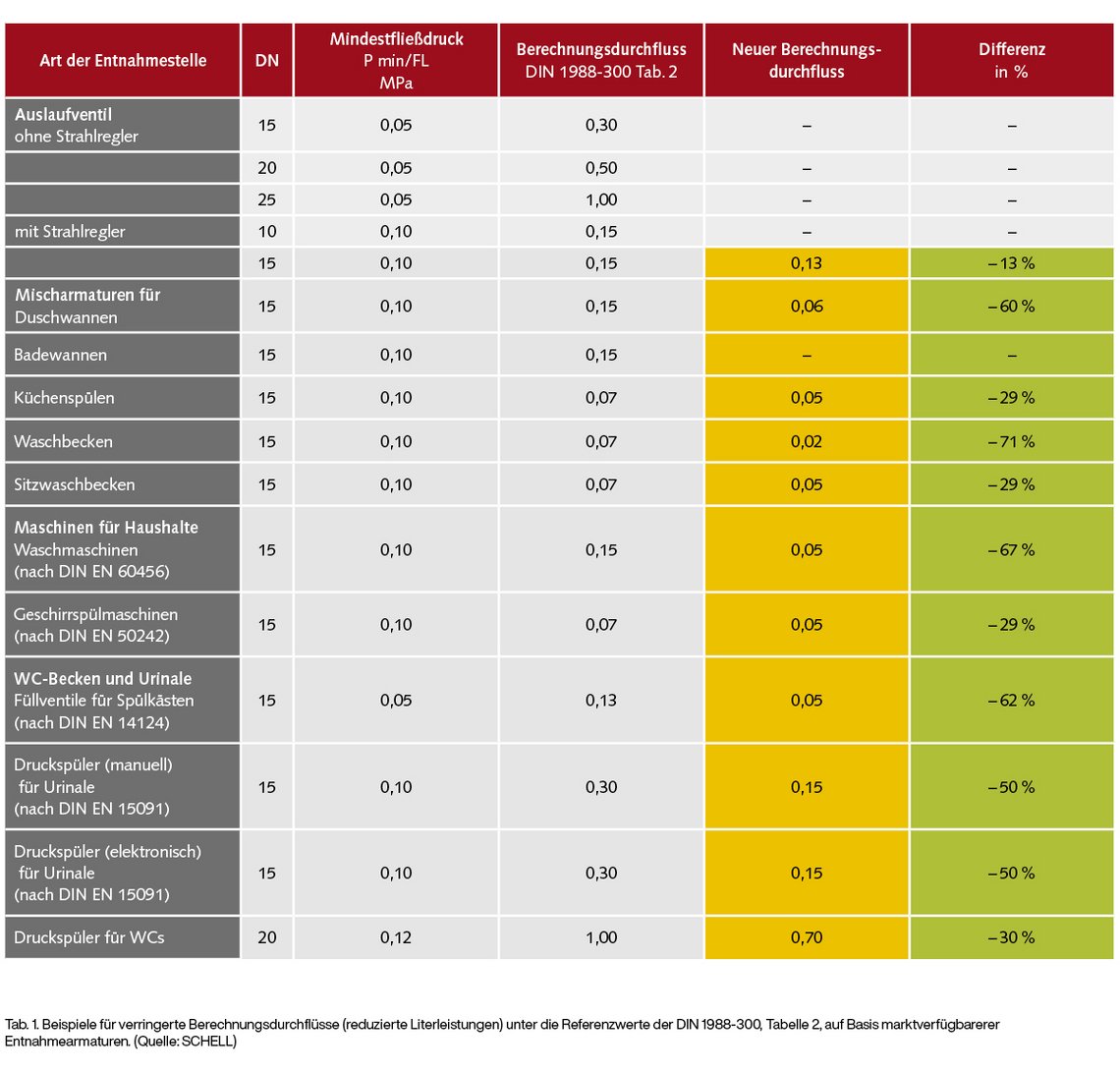

Achieving significant potential savings in the context of new building projects requires taking into account reduced calculated flows from tapping points. These lead to ‘leaner’ and therefore more cost-effective drinking water installations. Table 2 from DIN 1988-300 defines three groups of minimum flow pressures and calculated flows. Of these, only the tabulated values are typically included in the planning software used for drinking water installations. In a footnote to table 2, however, a section marked ‘Important information’ does state that the calculated flows may in fact be higher or lower than the values in table 2, and that planners must use the real-world calculated flows and not simply copy the values stored in the software:

“If manufacturer specifications for minimum flow pressure and calculated flow are below the values stated in the table, then planners have two options.

If the drinking water installation should be dimensioned according to the lower values, for hygienic and economic reasons, then this approach must be agreed with the developer and the design specifications for the tapping points (minimum flow pressure, calculated flow) must be included in these dimensioning calculations.

If the drinking water installation is not to be dimensioned for the lower values, then the tabulated values can be used. If manufacturer specifications are higher than the values stated in the table, the drinking water installation must be dimensioned using these higher values.”

Accounting for actual consumption and calculated flows from ‘white goods’

In addition to the availability of water-saving fittings, WCs and urinals, consumption values and calculated flows from washing machines, dishwashers, etc. (‘white goods’) are now significantly lower than at the time when the calculated flows from draw-off valves were calculated and included in table 2 for DIN 1988-300. Additional potential savings can be achieved here, which then lead to even ‘leaner’ drinking water installations.

Realising economic and ecological potential

When fit-out planners, working on behalf of the investor, use reduced calculated flows to achieve a significantly leaner dimensioning of the building’s drinking water installation, this can realise significant economic and ecological potential: together, all of these reduced dimensions – for piping, connectors, insulation and pipe clamps – result in lower initial investment and running costs. In turn, this also reduces space requirements in the separate ducts for hot and cold piping, which simultaneously increases usable space on each building storey.

Practical example: recalculation for a residential building with six apartments

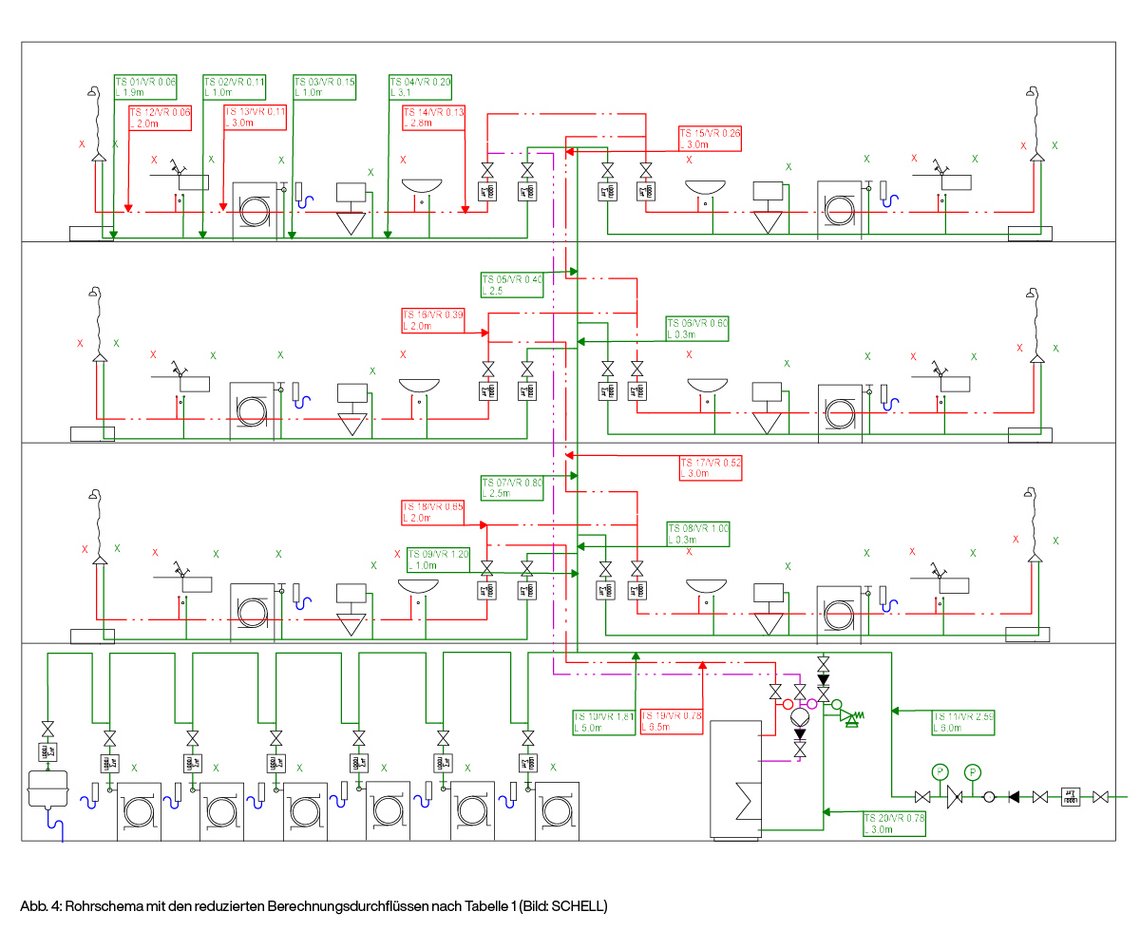

Güsgen’s bachelor’s thesis includes an impressive practical example that illustrates the corresponding calculations and potential savings. Based on the calculated flows for water-saving draw-off fittings and WCs available on the market (table 1) plus the values taken from table 2, DIN 1988-300, he completed a comparative calculation for a residential building with six apartments (figure 4).*

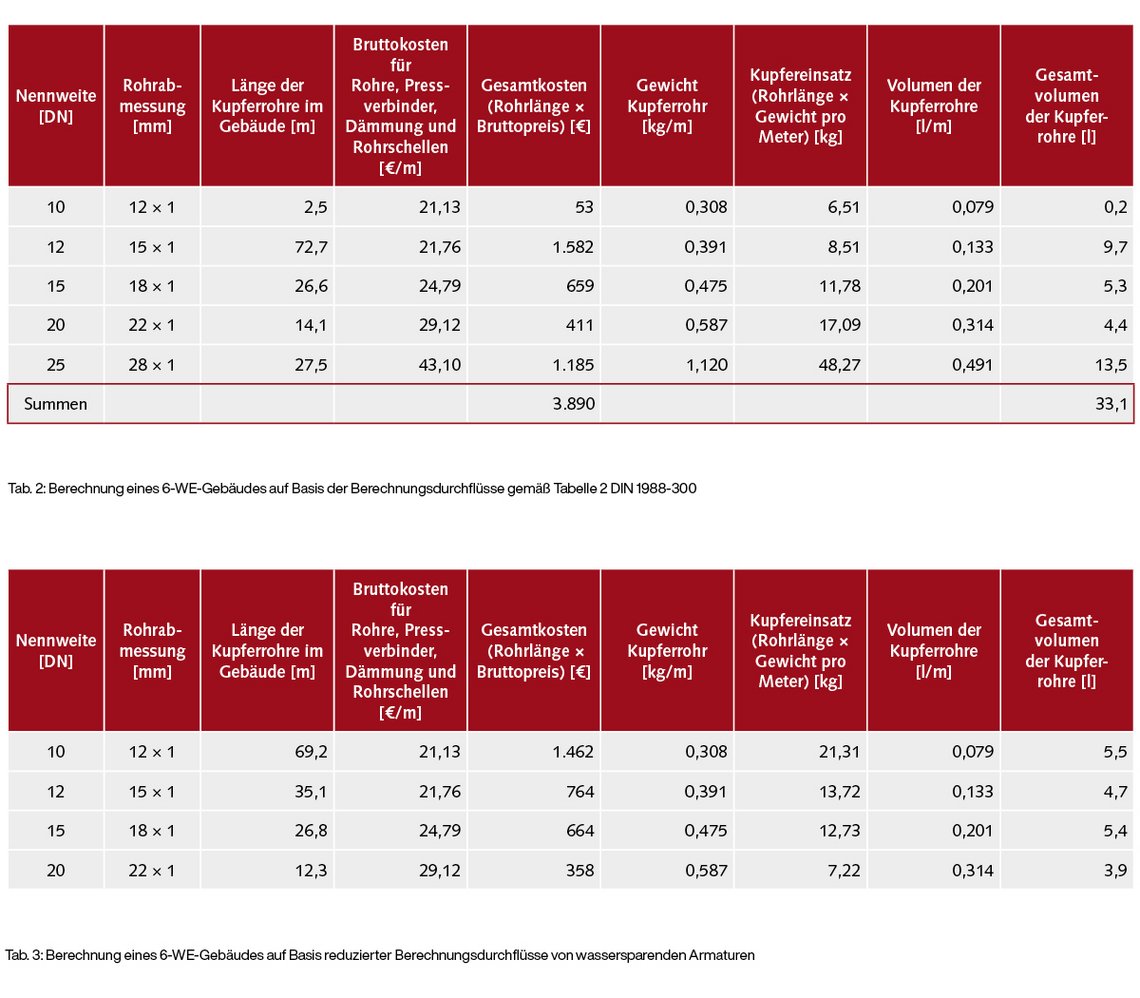

Results of comparative calculations

A comparison of the calculations reveals the magnitude of the ecological potential realisable if real values, from water-saving taps and fittings, are used to dimension the drinking water installation instead of theoretical values. The results of the comparative calculations are presented in tables 2 and 3. “As expected, these work to push pipe dimensions far into the lower end of the spectrum. In the context of the copper piping used in this building, this reduces the copper needed by 40 percent by weight. This is a really significant saving in ecological terms,” Arens concludes. Tables 2 and 3 also show how pipe lengths are reduced from around 73 m (for DN 12) and 2.5 m (DN 10) (calculated flows according to DIN 1988-300) to 35 m (DN 12) and 69 m (DN 10) (reduced calculated flows).

“Economically, however, these savings play a much less important role than the ecological benefits from reducing material usage. This is because, in monetary terms, the DN 10 dimension for piping, connectors, insulation and pipe clamps (in total EUR 21.13/m) is almost the same as for DN 12 (EUR 21.76/m). One reason for this is that the DN 10 size is still something of a rarity for installation dimensions. But this should change once DN 10 becomes more frequently installed in the future,” Arens says, explaining the results.

A detailed comparison between the two largest dimensions reveals the savings on initial investment that can be achieved for a larger-scale building. In this six-unit residential building, the dimension DN 25 becomes superfluous with lower calculated flows – and even the DN 20 dimension can be reduced in terms of length. In the case of these two dimensions, savings amount to no less than 78 percent: EUR 1,596 before and EUR 358 after. This is because the large dimensions for pipes, connectors, insulation and pipe clamps account for a disproportionate share of costs in large buildings. In summary, one can conclude that, despite the unfavourable general conditions as stated above, the initial investment for this building can still be reduced by 17 percent or around EUR 642. This comparison is based on gross prices for copper piping, press fittings, insulation and pipe clamps.

Further significant savings in running costs

In terms of day-to-day costs, additional savings can be achieved. First of all, reduced water consumption has a direct effect on annual utility charges for water and waste water. Energy costs are also reduced – since a smaller volume of drinking water needs to be heated and circulated at a specific temperature. These energy costs were not determined specifically as part of the bachelor’s thesis. “But they can be calculated indirectly from the reduced volume of water in the system,” Arens explains. “Accordingly, costs for this building would be cut by around 40 percent, calculated solely on the basis of metres of copper piping needed. This roughly 40 percent reduction in water volume also saves on the quantity of water needed for simulating specified normal operation with stagnation flushes during public holidays, for example.” To avoid having to conduct these flushes manually, a water management system like SWS from SCHELL can be used to perform these flushes automatically, which saves both time and water.

Planning with reduced calculated flows cuts initial investment and running costs

All three leading systems for ecological building certification – LEED, BREEAM and DGNB – include the topic of drinking water as a separate category in the context of ‘saving water’. None of these three systems takes the topic of drinking water hygiene into account, however. Arens: “This is the reason why we need to look at the bigger picture here.” In existing properties, for example, water withdrawals cannot simply be reduced below the calculated flows from DIN 1988-300 without compromising drinking water hygiene. This would result in drinking water simply stagnating in the installation – with potentially serious consequences for user health. As result, water withdrawals in existing properties can only be reduced to a point by water-saving facilities (see also here).

Arens describes the following example scenario: “If, for example, ‘old’ taps rated at 8 to 10 litres per minute are fitted to wash basins, as is often the case in existing properties, then they can often be reduced to 4.2 l/min (as specified in table 2, DIN 1988-300) by simply swapping out the flow regulator – if the drinking water installation was originally dimensioned on the basis of table 2, DIN 1988-300.”

In addition, none of the three systems account for the considerable economic and ecological potential that results from reducing the calculated flows, i.e. by reducing the litre-per-minute rating of taps and fittings. In the event of a new, professionally planned drinking water installation according to DIN 1988-300, these can significantly reduce the dimensions needed for piping, connectors, insulation and pipe clamps. “Planners do then need to take these reduced values properly into account, however,” Arens notes, concluding: “in this case, the water-saving measures mentioned are then one of the very few ecological approaches that can significantly cut initial investment and running costs. Accordingly, these cost-cutting measures should be a key aspect of all three systems by making pipe dimensioning mandatory and promoting good practice by awarding more points in the final grading.”

* Notes on calculations

1) To calculate residential building values, Luca Güsgen used the same Excel application as used in the ‘Meister’ qualification for the South Westphalia Chamber of Trades (BBZ Arnsberg campus), which is shared with participants for further use in the HVAC/sanitation industry.

2) For the pipe material, including gross prices for the price comparison, he chose Viega’s ‘Profipress’ product, designed as a T-piece installation in accordance with the German DIN EN 806 standard plus a serial mains. His calculations account for costs based on the length of the piping and insulation material, as well as the number of pipe clamps and the four connectors most commonly used.

3) The planning model avoids circulating heated drinking water to tapping points for hygienic and energy-saving reasons – since this typically transfers avoidable waste heat into pre-walls and sanitary facilities, and therefore indirectly into cold drinking water as well. The ‘max. 3 litres rule’ for stub lines (DVGW (A) W551) is also applicable here and was therefore used.

![[Translate to English:] Eingangsbereich des Boutique Fitnessstudios EVO Fitness Bel & Main in Wien.](/fileadmin/user_upload/blog/2024/Evo_Fitness_AT/Evo_Fitness_Bel___Main_Wien-Menue.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)