Project data

Year of completion/opening: 1970

Facilities: 25-metre swimming pool, diving tower, pool for non-swimmers, baby/toddler pool, steam baths and sun terrace

Most recent renovations: 2020

SCHELL products: Water Management System SWS, BE-K wired bus extender, LINUS Inox DP-C-T shower panel, COMFORT shower head

When the baths closed due to the pandemic in early 2020, the opportunity was taken to install new Schell stainless steel shower panels, combined with the Schell SWS Water Management System. This now gives baths operators and visitors alike peace of mind in relation to high-quality drinking water and exemplary hygiene.

One of the most important changes was the use of stainless steel as the perfect material for shower panels in public baths. Two other issues also needed to be addressed by the planned renovation works: first, a reduction in personnel costs for shower panel maintenance and second, ensuring that specified normal operation could be achieved automatically with stagnation flushes, which previously had been completed manually every 24 hours.

Optimum hygiene and comfort for shower users

A total of 18 of Schell’s LINUS Inox DP-C-T stainless steel shower panels were installed. These feature a corrosion-resistant housing made from premium brushed stainless steel in the quality grade 1.4404 (German V4A). The vandal-resistant, soft-stream COMFORT shower head with no-limescale nozzles also reduces maintenance work. The electronic shower panel variant chosen features CVD touch electronics for automatic closing with splashed water protection, plus an EN 1111-compliant thermostat with integrated safety lock in the event of a cold water line failure and a temperature lock at 38 °C. These user-friendly features ensure both convenience and effective anti-scalding protection for shower users.

Top priority: protection against infection

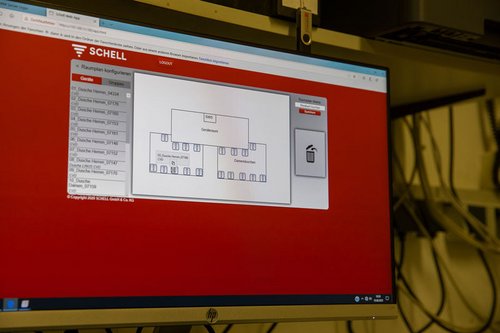

In light of closures caused by the recent pandemic in particular, measures had to be taken to ensure that water could not be contaminated by bacteria and cause illness in users as a result of water atomisation or aerosols. Accordingly, another key part of renovation work involved installing the Water Management System SWS from Schell. As a ‘host system’, the SWS Server is the central repository for all data. In addition, the 18 electronic Schell stainless steel shower panels were each equipped with a plug-and-play SWS bus extender cable BE-K. With the installation of electronic Schell stainless steel shower panels and their networking as part of the Water Management System SWS, effective – and very user-friendly – compliance with drinking water legislation was supported by the automated control and monitoring of stagnation flushes. SWS even makes thermal disinfection possible (compliant with DVGW Worksheet W 551), including full record-keeping. At the same time, Schell’s SWS helps to save water and energy without constraints on user comfort. This offers a useful balance between user comfort for visitors to the baths and efficient building operations.

“The Westbad piping system is old and, with no renovations since 2001, the pipes would have had to have been swabbed out,” reports the responsible District Master Builder Michael Kuhnle. “This was the main reason why we decided to make use of the Water Management System SWS” According to his calculations, the stagnation flush – which operates during pandemic-related shutdowns as well as the seasonal summer closure of several weeks – triggers for 30 seconds, three days a week, which corresponds to an additional daily water consumption of just under 9 l at each shower stall. This results in a total of 1,080 l of water for stagnation flushes, costing a maximum of EUR 5 per shower and per year. For Kuhnle, the benefits are clear: “This isn’t a cost factor but helps to improve overall hygiene.” Automated flush operations also avoid extra costs for personnel.

Looking to the future, the installed Schell Water Management System offers several advanced expansion options. At a later point in time, Ulm’s Central Building Management team could also opt to integrate electronic Schell wash basin, WC and urinal fittings into the Westbad SWS, for example.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)