Keeping building operations safe: how to maintain drinking water hygiene

According to the German Drinking Water Regulation, operators must take action to prevent water becoming contaminated – by Legionella, for example. A full exchange of water must therefore take place across all tapping points in the drinking water installation – ideally simultaneously – no later than every 72 hours. This is a difficult task to achieve, especially in larger properties. While manual flushing is always an option, this is time-, cost- and labour-intensive. In contrast, the SCHELL SWS Water Management System presents a hygienic, resource-friendly and cost-effective alternative that enables the automated execution of stagnation flushes.

SWS – the intelligent solution for hygienic drinking water management

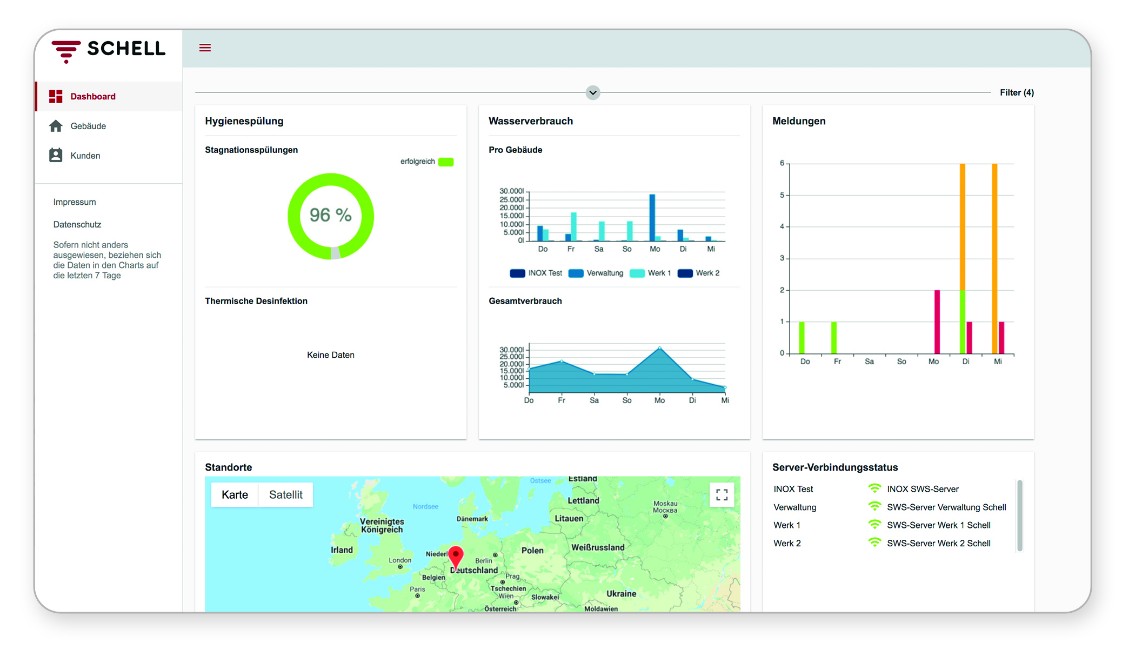

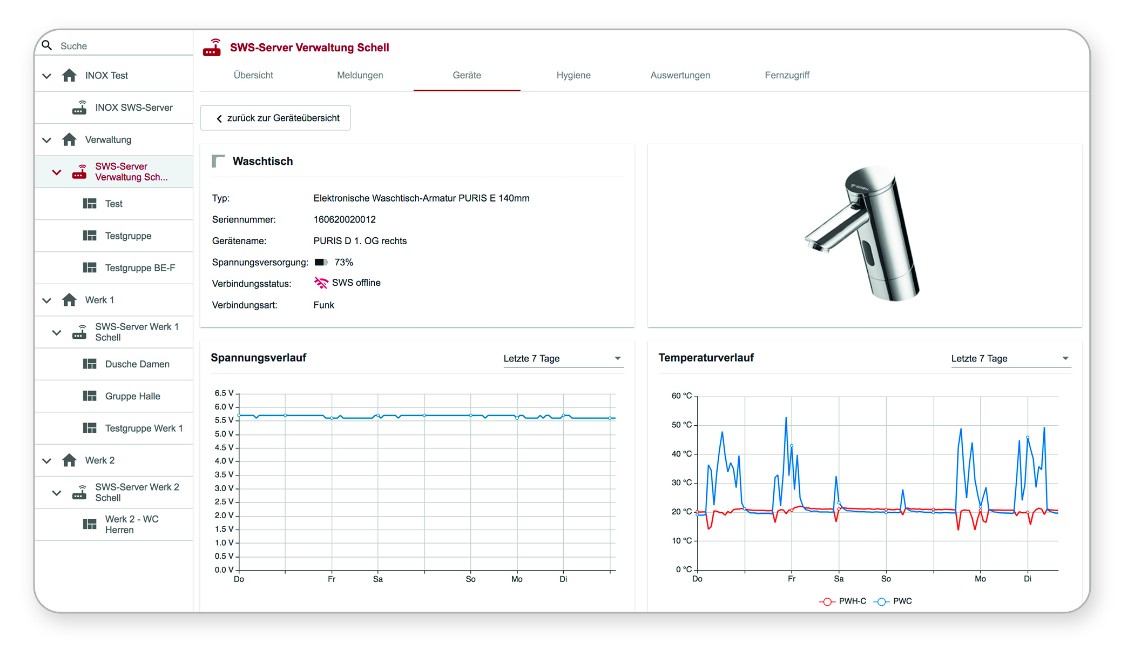

The SCHELL SWS Water Management System uses a central server to network together the SCHELL electronic fittings in a building. Hybrid wired/wireless connectivity is supported, which makes it suitable for both new developments and retrofits. In many cases, SWS therefore avoids the need for expensive renovations. Designed as a modular system, SWS can be easily extended by a wide range of other fittings. Each server supports a network that can consist of up to 64 subscribers. Programmed accordingly, SWS executes stagnation flushes automatically while logging these activities. Flushes can be scheduled or triggered in response to temperature changes, ensuring reliable protection for drinking water hygiene at all times. Full records are kept of all system processes. This guarantees a high level of transparency and record-keeping while providing building operators with key insights into conserving resources and optimising operations.

Other significant benefits offered by SWS when compared with the manual handling of stagnation flushes include time and personnel savings as well as a reduction in water and energy consumption, as only the absolute minimum quantity of water is used at all times.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)