Contamination with Pseudomonas aeruginosa: wet testing as a critical factor for drinking water hygiene – what you need to know

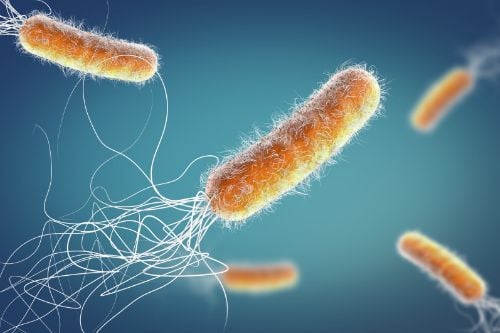

The bacterium Pseudomonas aeruginosa presents a serious health risk, especially for people with pre-existing conditions or those without a fully developed immune system. Strict protective measures and testing requirements therefore apply to any facilities that are primarily used by the public – which includes hospitals, residential and nursing homes, outpatient care facilities and day nurseries. Apart from these healthcare aspects, the remediation of a compromised drinking water installation will always be a very expensive and labour-intensive process. While avoidance strategies are well-known, contamination of installations by this rod-shaped bacterium is a regular occurrence. Parts already compromised during wet testing at the manufacturer are a key source of external contamination here. A safe alternative to this kind of testing is dry testing, which SCHELL uses wherever it is possible to do so. Some products – such as water meters, safety devices and pressure boosting stations – always require adjustment and calibration work, however. In these cases, wet testing becomes unavoidable. Planners and sanitation engineers should therefore keep the following in mind:

Pseudomonas aeruginosa: an invisible hazard

An ideal habitat for Pseudomonas aeruginosa

Water temperatures between 25 °C and a maximum of 45 °C provide the ideal habitat for this typical cold-water bacterium. However, Pseudomonas aeruginosa colonies can also grow (albeit more slowly) at temperatures as low as 10 °C. To replicate, this bacterium needs nothing more than a source of carbon from the air: unlike Legionella spp., for example, this means Pseudomonas can contaminate wet surfaces fresh from the factory floor.

Health risks from Pseudomonas aeruginosa

Pseudomonas does not normally present a health hazard to healthy individuals, but the risk increases with skin injuries, the introduction of foreign objects such as catheters and pre-existing conditions like cystic fibrosis. Other high-risk groups include people who have been discharged from hospital into their home environment before they are fully recovered and children, who do not yet have a properly mature immune system. This is why annual testing after commissioning – or also after extensive renovation work – is mandatory both within the healthcare sector and for childcare facilities.

How does Pseudomonas aeruginosa get into drinking water installations?

Pseudomonas ends up in drinking water installations if contaminated parts have been used. These parts become contaminated from the water that manufacturers have used for wet testing and calibration work. Even if this water is regularly replaced, there are still no assurances that it is then ‘microbe-free’: this is because bacteria can also colonise the surfaces of pipework and storage containers, from where they can re-enter the testing water again at any time.

Wet testing: a contamination risk

Wet testing has long been the standard procedure for testing leak-tightness and measuring product flow time in the fittings industry. What was not known until about ten years ago, however, is that this procedure harbours the risk of contamination with Pseudomonas aeruginosa.

How wet testing is done

In wet testing – i.e. conventional leak-tightness testing – the fitting is screwed to the mains connection, filled with water and tested for constant pressure. For functional testing, the fitting is connected to a water circuit and the flow time – i.e. the trigger time – is measured to ascertain the time needed from opening to closing.

Problems with wet testing

After wet testing is complete, getting the fitting dry is then essentially impossible – neither by blowing out nor with hot air. Accordingly, it is therefore impossible to exclude the possibility of water residues being present – along with bacteria – in the fitting. This is especially true near to seals, where bacteria preferentially accumulate. If fittings have metal parts, there is also a risk of corrosion and corrosive damage. If this damage then flakes off later, this can cause clogging and prevent the fitting from working properly.

A checklist for planners and installers

For these reasons, planners and installers should always use dry-tested parts – like sanitary fittings from SCHELL – whenever and wherever possible. These parts naturally fully meet the criteria for hygienically safe surfaces that have contact with water (cf. DVGW W 551-4 and VDI 6023 Part 1). In tender documents and purchase orders, planners and installers should also explicitly request hygienically safe parts in the general section. Some parts – such as water meters, electric instant water heaters, safety fittings and pressure boosting stations – do require wet testing as part of their production process, however. In this case, check the manufacturer’s guarantees for hygiene from factory to point-of-use (cf. DVGW W 551-4 (A)). These documents should also be provided for your own peace of mind.

Wet testing – a risk factor for hygiene

In the healthcare sector and childcare facilities in particular, all of the products installed must be hygienically safe. Above all, this means they must be free of Pseudomonas aeruginosa contamination. Wet-tested parts harbour the risk of containing water residues that may, in turn, be colonised by Pseudomonas. For this reason, SCHELL uses hygienically safe dry testing wherever possible – and is one of the industry’s leading pioneers in this area.

Go here to find out more about the dry testing process and its benefits.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/b/csm_symstemloesungen_e2_thumb_6bca267f26.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/images/menu/menu_service_downloads_broschueren.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_menu_unternehmen_ueber-schell_awards_f6cec25b1d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/0/csm_menu_unternehmen_ueber-schell_wasser-sparen_41036d2dd9.jpg)