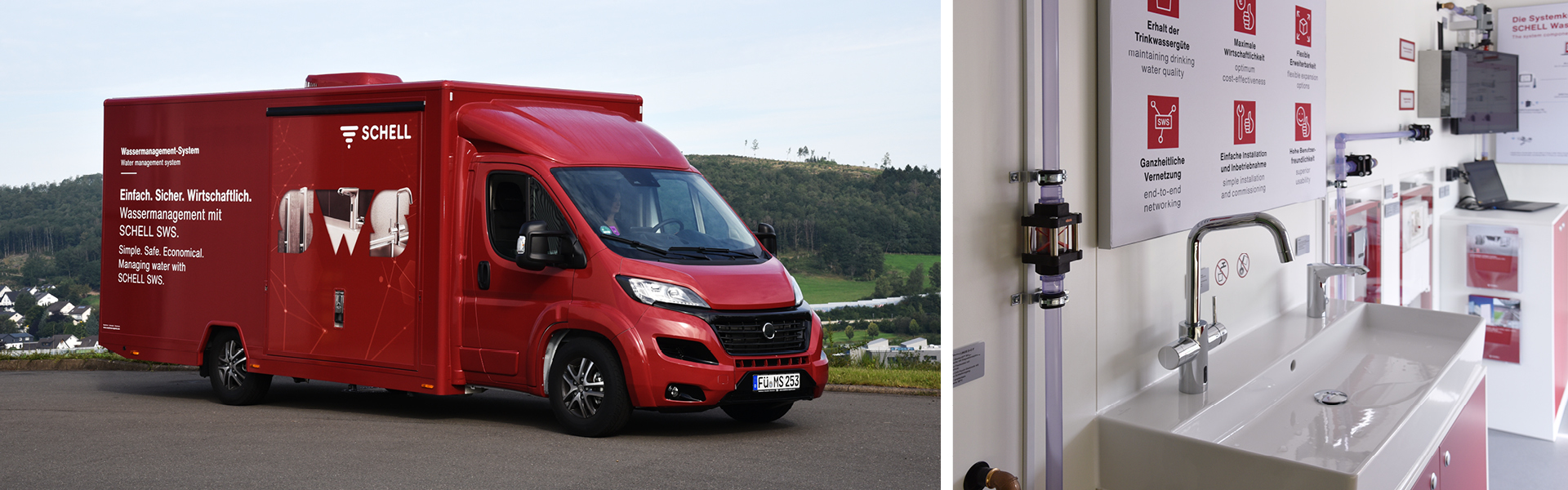

SCHELL Live

Buchen Sie jetzt einen Besuch des SCHELL Mobils in 2023.

Wenn das SCHELL Mobil vor Ort ist, erleben Sie hochwertige SCHELL Produkte und können unsere Profis zu allen Einzelheiten befragen.

Weiterlesen

4 Minuten Lesezeit

Wenn das SCHELL Mobil kommt, erleben Sie unsere Produkte live in Aktion. Am bereits seit zwei Jahren im Einsatz befindlichen SCHELL Mobil 1 haben unsere Kunden so großes Interesse, dass es stetig ausgebucht ist. Zudem ist der Wunsch an seinem internationalen Einsatz groß. Um allen Interessierten gerecht zu werden, haben wir daher unsere Flotte verstärkt und ein zweites SCHELL Mobil auf die Straße gebracht. Unser zweites Fahrzeug geht ab Spätsommer 2023 für Sie auf Tour.

Vor Ort zeigen Ihre Ansprechpartner Ihnen hochwertige SCHELL Produkte und Lösungen zum Erhalt der Trinkwassergüte. Ihre Schwerpunkte setzen Sie dabei selbst, denn in den SCHELL Mobilen ist eine große Auswahl des gesamten Portfolios vertreten. Sie erleben Waschtisch-, Küchen-, Dusch-, WC-, Urinal- und Leckageschutz-Armaturen in Aktion – wie zum Beispiel die mehrfach ausgezeichnete, berührungslose Waschtisch-Armatur XERIS E-T.

Auch digitale Lösungen finden sich an Board. Erhalten Sie einen Einblick, wie einfach elektronische SCHELL Armaturen mit SCHELL Single Control SSC parametriert werden können.

Beliebtes Highlight in beiden SCHELL Mobilen ist der simulierte Wasserkreislauf. Er macht den Wasserfluss von z. B. Stagnationsspülungen, die via mit SWS vernetzten Armaturen ausgelöst werden, sichtbar und direkt erlebbar.

Die bewährten Produkte unseres mobilen Showrooms sind auch im zweiten SCHELL Mobil an Bord. Ergänzen konnten wir die Ausstattung durch den jüngst mit dem PLUS X Award prämierten MODUS Einhebelmischer mit Bügelgriff. Auch weitere Eckventile aus unserem breiten Portfolio fanden ihren Weg in den Showbereich unterhalb der Waschtischarmaturen. Natürlich wurde auch das erste SCHELL Mobil aktualisiert: Das platzsparende Geräteanschlussventil und den Duschkopf Comfort Flex können Sie in beiden Mobilen entdecken. In beiden Mobilen finden sich Produktschilder in 8 Sprachen.

Bei der Buchung eines SCHELL Mobils können Sie vorab Ihre Interessensschwerpunkte angeben. Wir informieren dann beispielsweise passgenau zu SCHELL Produkten, die sich im Gesundheitswesen bewähren oder Lösungen für Sanitärbereiche in Freizeit- und Sportstätten. Auch Einzelthemen wie Verbrühungsschutz, Nutzerhygiene, Trinkwasserhygiene und Wassermanagement können wir Ihnen live bei Ihnen vor Ort im SCHELL Mobil präsentieren. Auf Wunsch schulen unsere Berater auch Ihre Mitarbeiter zu den Vorteilen vernetzbarer, berührungsloser Armaturen – allgemein oder für konkrete Projekte. Sprechen Sie uns zu den Details gerne im Vorfeld an.

Das zweite SCHELL Mobil startet mit einem vollen Terminkalender: Internationale Tour-Halte in Belgien, Österreich, Italien und den Niederlanden sind für die zweite Jahreshälfte 2023 bereits gebucht. Das hat einen guten Grund, denn das zweite SCHELL Mobil ist von vornherein mehrsprachig ausgelegt.

Sie möchten auch Ihren Kunden einen Einblick in die Funktionsweise von SCHELL Produkten bieten? Dafür stattet Ihr Ansprechpartner aus unserem Außendienst Sie gerne mit Info-Material aus. So können Sie mit kostenfreien Flyern und Plakaten Ihre Kunden im Vorfeld über Ihre Veranstaltung rund um das SCHELL Mobil informieren.

Mit dem SCHELL Mobil Nummer 2 haben wir unsere Tour-Kapazitäten erweitert und können Sie europaweit besuchen. Ihre Vorteile: Wir kommen zu Ihnen und Sie haben keinen Aufwand. Sie können SCHELL Produkte in einem funktionsfähigen Wasserkreislauf live erleben und Ihre Mitarbeiter schulen lassen. Dabei simulieren unsere SCHELL Mobile sogar die Funktionsweise von SWS. Das SCHELL Mobil 2 ist schon für die erste europaweite Reise gebucht. Wenn Sie unsere Produkte in einem der beiden SCHELL Mobile selbst erleben oder einen geeigneten Tour-Halt empfehlen wollen, vereinbaren Sie einfach einen Termin mit dem SCHELL Außendienst und wir kommen mit SCHELL Mobil 1 oder 2 samt Standbesatzung exklusiv zu Ihnen. Zuständige Ansprechpartner für Ihre Region finden Sie über die Ansprechpartnersuche.

SCHELL Live

Wenn das SCHELL Mobil vor Ort ist, erleben Sie hochwertige SCHELL Produkte und können unsere Profis zu allen Einzelheiten befragen.

WeiterlesenPlanungshilfen - SCHELL Live

SCHELL bietet nicht nur innovative Produkte und verlässliche Qualität, sondern auch ein umfangreiches Service-Angebot, das Ihnen das Leben leichter macht.

WeiterlesenPlanungshilfen

Das Infoportal Bauspot.de dient Planern und Architekten zur Inspiration und zur Recherche. Kurzbeschreibungen interessanter Produkte können von den Nutzern des Portals als „Spots“ an eine...

Weiterlesen